Reuse 100

Overview Product Description Reuse 100-150 Times Plastic Coated Formwork Lumber Beam forConcrete Construction We called

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | TR006 |

| MOQ | 1000m |

| Feature | Super Waterproof |

| Length | 3000mm or Customized |

| Color | Black |

| Transport Package | Bundle |

| Specification | 40x60mm, 50x70mm |

| Trademark | TRICO |

| Origin | Hebei, China |

| Production Capacity | 500tons/Month |

Product Description

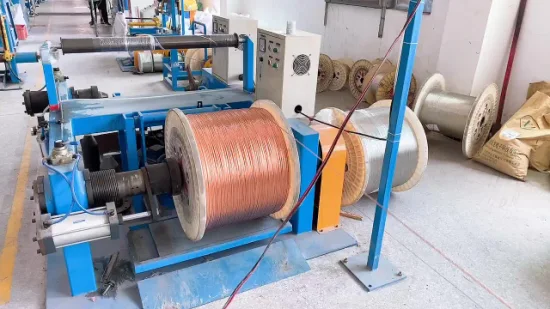

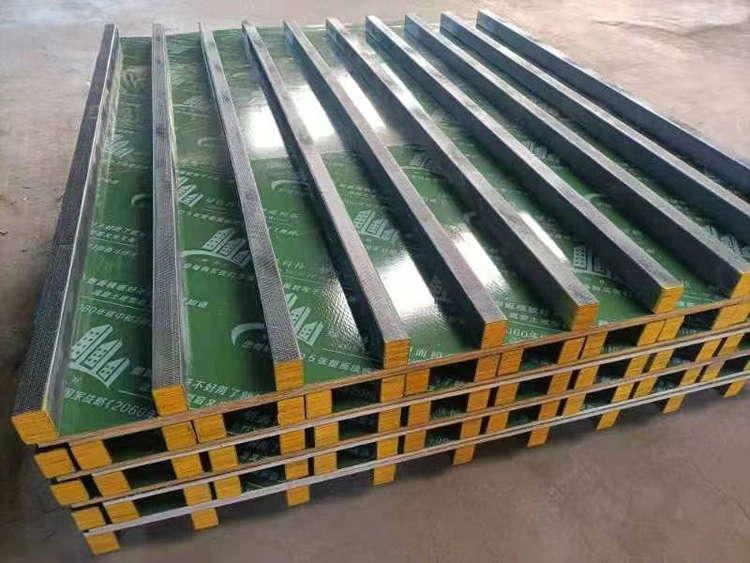

Product DescriptionReuse 100-150 Times Plastic Coated Formwork Lumber Beam forConcrete Construction

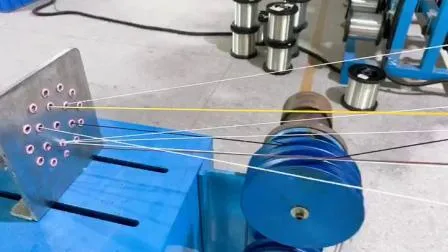

We called it "Rigid stud " in China, this is a new type of green building material.It is processed byusing waste wood templates on construction sites as raw materials, Processed by fully automatedproduction equipment and relying on advanced production technology through regeneration andrecycling technology.Due to its surface being covered with anti slip plastic resin, so it is of Superwaterproof and Highly Bearing Strength feature.The wooden side of the scientific and technologicalbuilding adopts a vertical structural core, which has strong toughness, no delamination and nofracture, more than 100 turnover times, a durable period of more than 10 years.

Due to its Improve project quality and save money save material, it was immediately welcomed byconstruction companies and has an unprecedented market development spacet.

| Product name | Plastic Coated Lumber Beam |

| Size | 50mm x 70mm / 40 mm x 60mm and can be customized |

| Thickness | 3 Meters and can be customized |

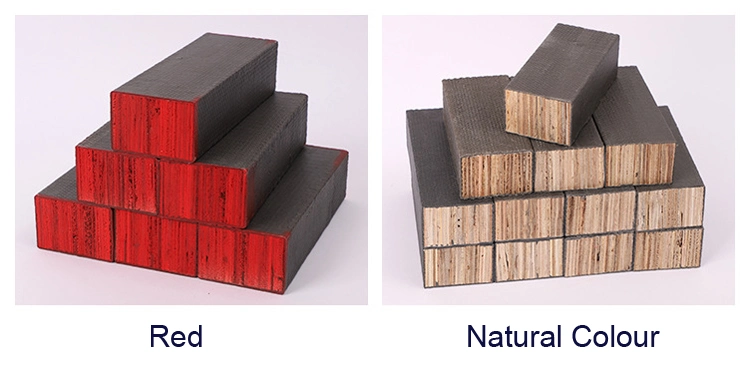

| Surface Treatment | Coated with Anti-Slip Black Plastic |

| Core | Recycle Plywood |

| Glue | Phenolic ,WBP ,MR |

| Moisture Content | 8%~14% |

| MOQ | 1000 Meters |

| Reusable time | More than 150 reusable times |

| Advantage | lightweight, high strength, waterproof |

| Color | Grey / Customized |

| Bear temperature | -35ºC~120ºC |

Detail of the Plastic Coated Lumber Beam -Rigid Stud

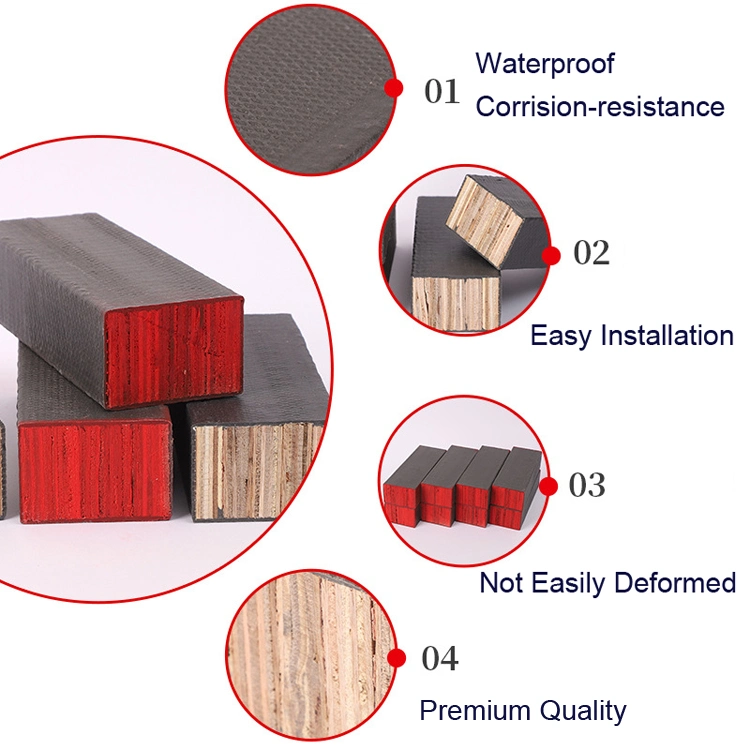

1. Light Weight: the density of Plastic Coated Lumber Beam is only about 2kg per meter, itis easy to deliver, dismantle and install.

2. High Tenacity: The Formwork Plastic Coated Lumber Beam is not easy to break off becauseof Plastic Coated .

3. Good Proofing: Polymer outer package, prolonging the service life,the Formwork PlasticCoated lumber Beam is good at waterproof, acid proofing, alkali proofing, moth proofing, andcorrosion resistance.

4. Environment Friendly: The Formwork Plastic Coated lumber Beam belongs to renewableresources, could be used many time. And without poison, no damage to health.

5. Good Straightness: The Plastic Coated Lumber Beam is not easy to deform.

| Performance comparison | Plastic Coated Lumber Beam | Common Wood | Common square steel | Common steel pipe |

| Drop Test (10m) | Not broken | Broken | Deformed | Deformed |

| Wear-resistance | Good | Poor | Good | Good |

| After water absorption | no absorption no deformation | Deformed | Rusty and deformed | Rusty and deformed |

| Nail | Easy | Easy | Unworkable | Unworkable |

| Expansion shrinkage | High | non | Low | Low |

| Residual value of scrap | Unwanted | Unwanted | Need | Need |

| Reusable times | 100-150 times | 20-30 times | 80-100 times | 80-100 times |

Bundle

More ProductsPlastic Formwork

The Hollow Plastic Formwork Board is becoming the new favorite with its characteristics of environmentprotection, energy saving, recycling, anti-water and anti-erosion. It will replace the traditional Plywood in theconstruction.

Galvanized or Painted Adjustable Steel Props

Prop is one of a system structure members used temporary to support the loads during construction.The forces arising from this loads must be fully resolved, using Props or Columns to provide all thesupport needed for the work under construction, such as beams, formwork and etc.

Our Services- Formwork Tie Rod System

- Aluminium Formwork Wall Tie System

- Scaffolding System

- PP Hollow Plastic Formwork

- Steel Formwork Panel with Plywood Forming System

- Other Plastic Building Materials

1. Quality: Strictly control the quality through three levels. First level, quality test on the producing line.Second level, quality test during warehousing. Third level, quality test before loading.

2. Timeliness: 24 hours online. Provide consulting and quotation services for customers all the time.

3. Veracity: Strictly follow the customer standard to ensure the tolerance range and meet customer'srequirement.

4. Integrity: If the customer complains about the quality of the products, our company will activelycooperate with them to solve the problem. If it is the responsibility of our company, we will bear thecorresponding responsibility and compensation.

5. Longevity: Establish good long-term relationship with customers.

Company InformationTRICO was founded in 2002. As an expert in the field of formwork and scaffolding,TRICOis committed to providing better products and services to customers in the globalconstruction industry.TRICO has a wide range of product lines, including the production and supply of fullsystem of building formwork, scaffolding and related components, and has realizedthe "1+N" one-stop service mode. Theproducts sell well in more than 90 countriesand regions, winning the recognition and trust of business partners around the world.TRICO's R&D team is experimenting and optimizing products every day. The endlessimprovement and perfection is the gene of TRICO culture. TRICO's mission is to promotethe quality improvement, cost reduction and environmental protection and efficiencyenhancement of global buildings. Let's work together to make it easier to build houses anywhere in the world!

Contact InformationHebei Trico Trade Co., Ltd

(Shijiazhuang Trico Hardware Products Co.,Ltd)

Add: Room 1005, Zhongyuan Building, No. 368 Youyi St., Shijiazhuang, Hebei, China.

Attn: Victor Lu (Sales Manager)